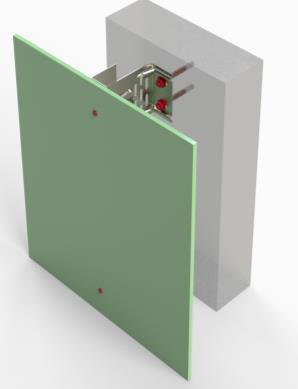

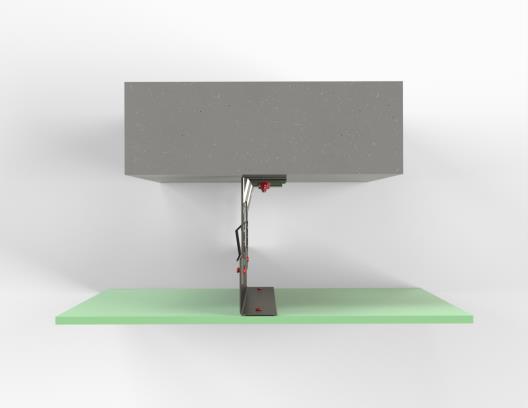

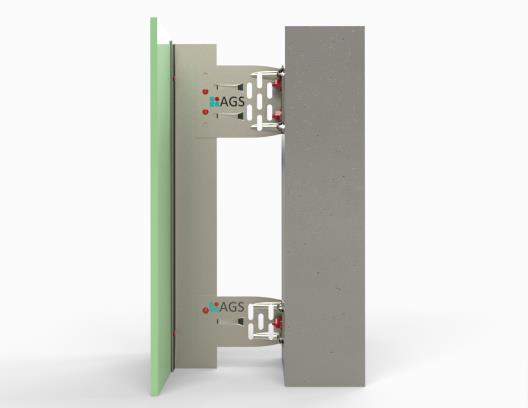

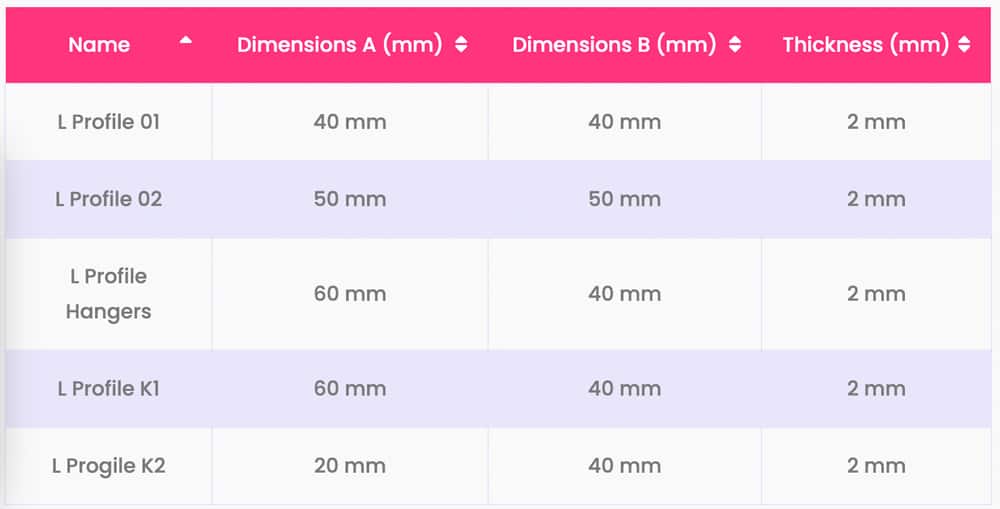

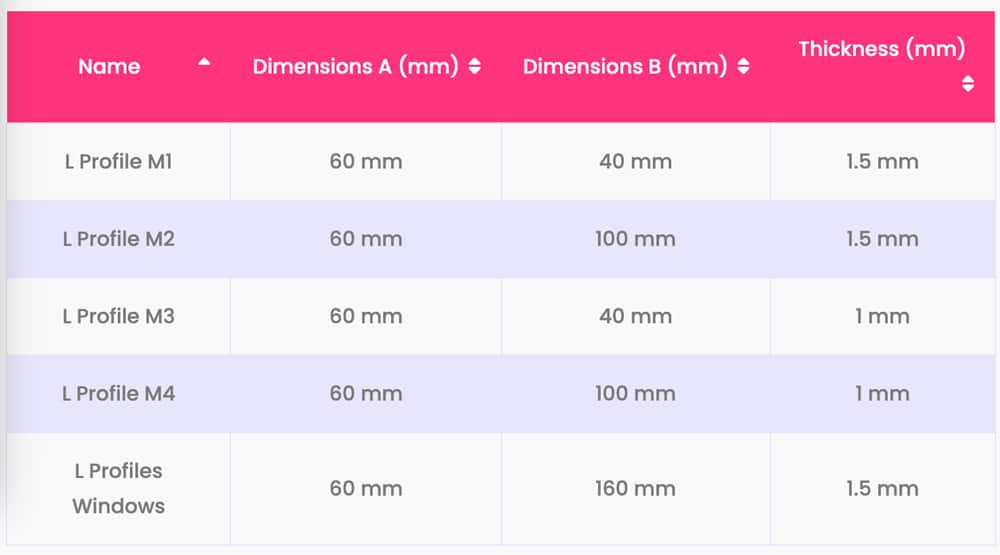

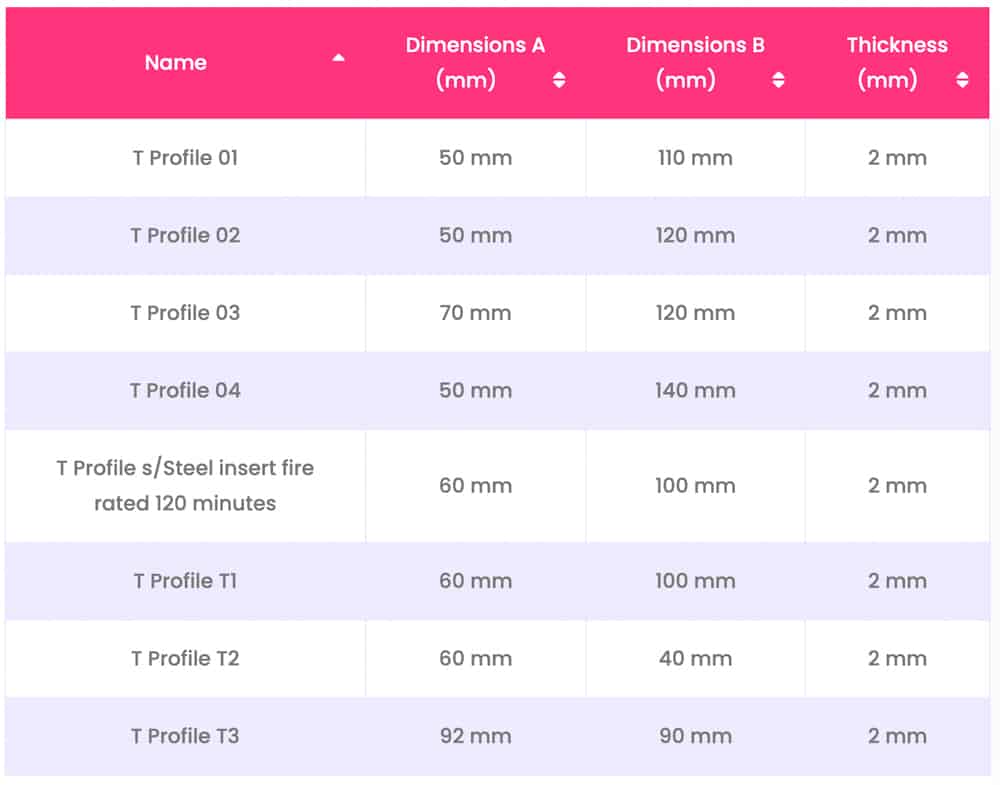

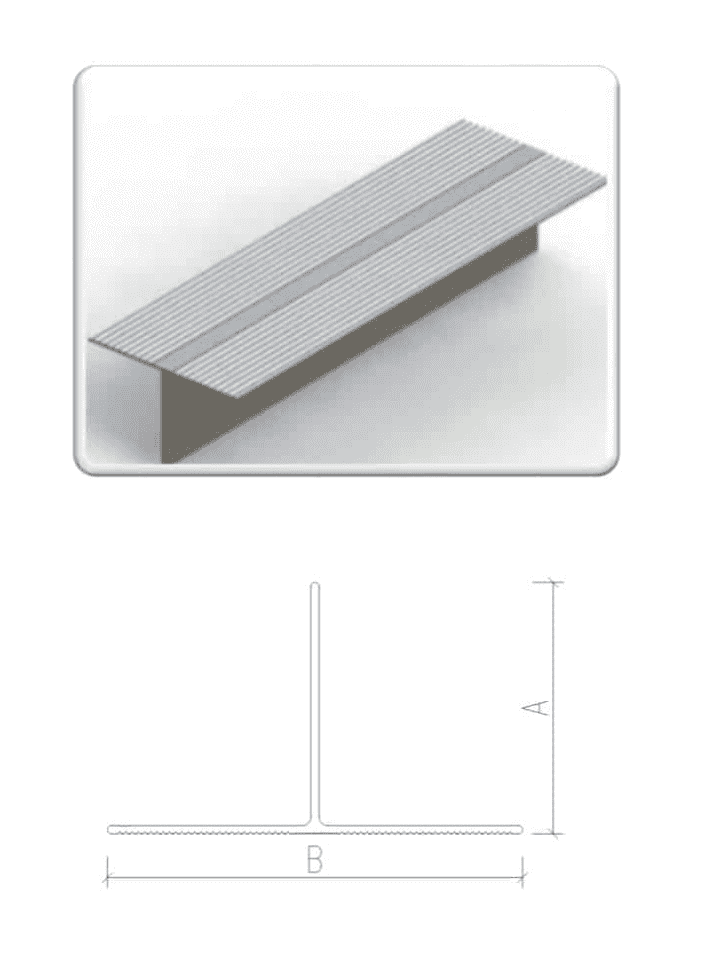

This system is suitable for face fixing cladding Our AGS – T Profiles and L Profiles are fixed using AGS brackets, mounted through single and double brackets. AGS Single brackets absorb wind loading and allow for expansion and contraction.

AGS Double brackets absorb both vertical dead loads. AGS single and double brackets spacing is determined by cladding options such as the dimensions and weight of the facade cladding, project location for wind loads calculation. Bracket spacing in the system is determined by the weight and dimensions of the facade cladding.

Face Fix Systems

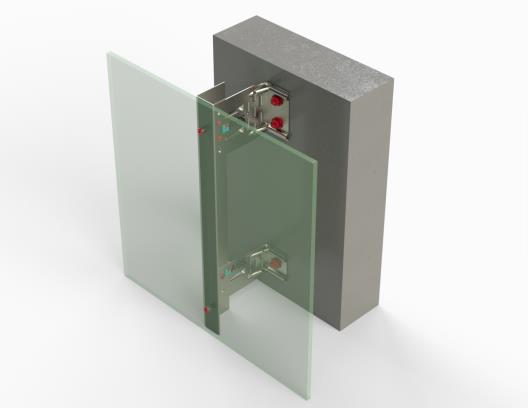

A ventilated façade can be constructed using different tested and certified framing systems, each with their own advantages in terms of aesthetics, installation, and performance, to fix the cladding panels on a sub-frame. Cladding panels must be installed on a sub-frame of sufficient strength and permanent durability. Quality and/or treatment of the sub-frame must be in accordance with applicable building standards.

Screw fix to timber:

The easiest and most cost-effective way of fixing decorative cladding is onto a tanelised timber substrate using mechanical fixings. These vandal-resistant torx fixings can be powder coated to colour match the board and are generally used with a neoprene gasket as protection for the timber and to give a shadow line effect.

Rivet fix to aluminium subframe:

For a lightweight and low-maintenance alternative to timber, decorative cladding can be fixed to an aluminum sub frame. The system is fully adjustable to accommodate even the most awkward and uneven scenario. It is available with cavity ranges from 50mm to 420mm allowing the consistent smooth lines cladding is known for.